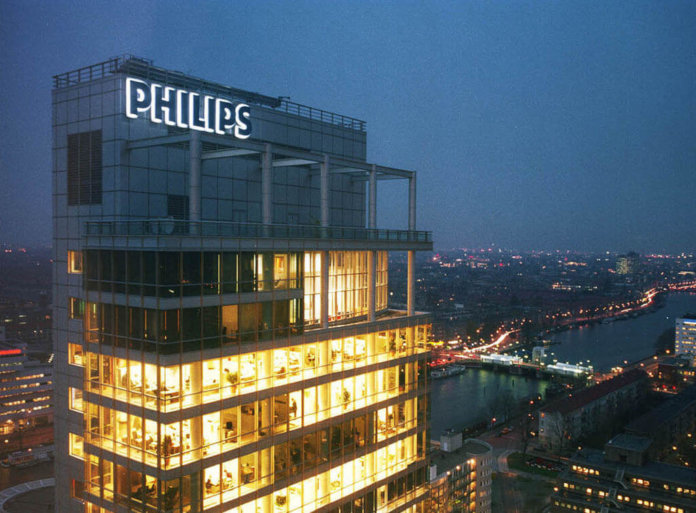

When the Philips Corporation launched their sustainability vision in 2012, it was seen by many as a brand new venture into furthering 21st-century technology. There can be no question, the Dutch-based company was viewing all of their future projects through the lens of long-term sustainability, both for the company as well as the planet.

At the time, the company put forth their vision as such: “At Philips, we strive to make the world healthier and more sustainable through innovation. Our goal is to improve the lives of 3 billion people a year by 2025. We will be the best place to work for people who share our passion. Together we will deliver superior value for our customers and shareholders.”

Today, the company is known for its expertise in three main areas, Healthcare, Consumer Lifestyle and Lighting and Innovation Group & Services. At one point, Philips was the largest manufacturer of Lights & Lighting components in the world. In 2012, the bold plan was heralded as having an eye to the future. However, if you understand where the company came from and what their journey has been from their 19th-century founding, the move really appears to pay homage to the company’s early days.

First Generations

The company was founded by the Father and son combination of Frederick and Gerard Philips in Eindhoven, in the Netherlands in 1891. Right from the beginning, Philips was founded with an eye towards the future. Though electrical components were still sparse in their widespread use, the Phillips father and son set up a factory to produce parts for electric street lamps. Frederick, a banker by trade, set up a factory where they would produce carbon filament lamps and other electro-technical products.

Within a few years, Frederick’s youngest son, Anton would join the family business. His engineering degree would prove to be invaluable for the growth of the family business. Anton suggested that they expand their product line to include metal filament lamps in 1908 and, four years later, the Philips lightbulb factories.

The Phillips family was clearly correct in their estimation of the market demand for these products as success came relatively quickly. They were primarily an export company, sending their product all over the world including to one particular customer in Russia. It turns out these are requested a large order of their product to light up his Winter Palace.

In 1912, the family listed the company on the Amsterdam stock exchange. Two years later, they would establish the NatLab, a world-renowned product research laboratory. It would seem that the concept of innovation and staying at the leading edge of technology is not something that is a relatively new phenomenon in the company. It appears to be something that was ingrained in the company’s DNA right from the beginning.

Expansion into Health Tech and Consumer Electronics

Their entry into the field of health technology, one of the company’s major pillars even today, was not something that was planned. In the article, The art of medical imaging: Philips and the evolution of medical X-ray technology, J.A.M. Hoffman explains why.

“During World War I, when it became increasingly difficult for physicians in many European countries to have their defective X-ray tubes repaired or replaced, since most of these tubes were produced by German-based companies, Dutch physicians made an urgent request to Philips, asking the company if they could repair their X-ray tubes. Because Philips had the necessary expertise in glass and vacuum technology, the company complied with the request, and so the Philips Research Laboratory (founded in 1914), took on the repair of these tubes.”

By 1916, Philips began designing and manufacturing their own X-Ray glass tubes and have been a key player in the health tech field ever since.

Another area where the company saw rapid development and innovation was with consumer electronics. By 1927, Phillips began their production of radios and within five years, would become the world’s largest producer of radios and radio tubes.

In 1939, Phillips introduced there first Philishave electric razor. Though the product would undergo constant change and Improvement, the electric razor is still a key item in the company’s full product line. It is sold in the United States even today under the brand name Philips Norelco.

As 20th-century consumer tech evolved, Philips was right there at the forefront. They introduced their lines of televisions, stereos and cassette players, LaserDisc machines, as well as ushering in the era of the compact disc. The company very easily could have just stuck to the script of other century-old legacy companies that came before them. That is to try to stay somewhat ahead of the technology curve and as each new innovation hits the mainstream, try to put out a decent product with your brand on it.

But Phillips wasn’t content with being a legacy company. They wanted to embrace the bold spirit of innovation that helped the company grow from its first few years and decades. In a way, they embraced innovation in 2012 in much the same way they did in 1912.

Philips Green Production Initiatives

Philips has been involved with the green energy movement as far back as the early 1990s, however, they didn’t set specific efficiency targets until their updated EcoVision document in 2007. The main production engine behind this green approach is their EcoDesign approach which the company describes this way:

“EcoDesign is an approach that considers all aspects of product development and design. This includes life-cycle assessment to determine the environmental impact at each stage of a product’s life from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling. The EcoDesign process led Philips to define six key Green Focal Areas for improved environmental performance – Energy, Packaging, Substances, Weight & Materials, Circularity and Lifetime.

In 2011, Philips earned a Gigaton Award by the Carbon War Room “for its EcoDesign process — identifying environmental impact in terms of energy efficiency, hazardous substances, take-back, recycling, weight and lifetime reliability.”

Around that time, Philips won the $10 million L Prize for their design for a high-efficiency light bulb. By 2015, their efforts in green production processes saw them surpass a key milestone ahead of schedule. In February of that year, Philips saw, for the first time ever, more than 50% of their total sales in the green product category.

“Achieving our EUR 2 billion Green Innovation target ahead of time is a clear proof of accelerating sustainable business and value creation across the company. We now improve the lives of 1.9 billion people[3], demonstrating solid progress towards our EcoVision commitments”, said Jim Andrew, Chairman of the Sustainability Board and Philips’ Chief Strategy & Innovation Officer.

Honoring the Past with an eye on the future

If the future for Philips looks bright, it’s likely because it’s being lit with high-efficiency green tech light bulbs. This product is just one of many that are helping Philips achieve the rare dual feet of economic success in the marketplace while, at the same time, making the world a better place. And while Frederick and Gerard Phillips could not have envisioned what the world would look like in 2018, they likely wouldn’t be surprised by the spirit of entrepreneurship and the quest to improve the world through innovation that still exists in the company today.