For nine generations the art of shoe-making has been transmitted in the Dutch van Bommel family. Succeeding centuries of high quality manufacturing, the three brothers Reynier, Floris, and Pepijn van Bommel are today running the family business with no diminished success and with a few innovative brands added. In a Q&A Reynier van Bommel, CEO of the van Bommel business, talks about their family heritage and about the shoe industry.

The start of the Dutch van Bommel shoemaking history can be traced back to the move of the talented shoemaker Reynier van Bommel from his city of origin Dongen to the city of Breda in 1706. The talent of Reynier van Bommel was inherited by his sons Adrianus and Christianus who, 30 years later, became master shoemakers in Breda. Both his sons and grandsons became shoemakers and moved to Moergestel. When Reynier van Bommel moved to Breda, he got the citizenship of the city and his talent and profession was protected by the craftsmen’s guild of the city from then onwards. This gave him and his family the official permission to be part of the shoemaking trade.

The official beginning of the family business as we know it today started when the grandson of Reynier van Bommel, Johannes Petrus Bommel together with his son Johannes Franciscus were registered as “shoe and boot makers” in 1853. Around the year 1880, the business expanded including more than 60 shoemakers due to the huge demand on military footwear during the Franco-Prussian war.

Johannes Peter, Johannes Fransiscus’s son passed away in 1887 at the age of 51. His widow, Johanna van Dinter, who was left behind with 7 children, continued her husband’s work with the help of her two sons Franciscus Johannes and Michaël August. The inspiring team was behind turning the traditional family business into a modern and mechanised shoe factory.

The wave of mechanisation of the shoemaking industry in the first few years of the 20th century led to overproduction and prices fell. During the war years (1914-1918), the van Bommel exports dropped both domestically and abroad and the family was forced to stop making their traditional quality shoes and to start producing prescribed “government shoes” due to a government statutory regulation for production standard that came into effect in 1918. The government stepped in again but this time to decrease the unemployment in the shoe industry in the Netherlands by issuing a “shoe act”. The act limited importing shoes to the Dutch market. As a result, the number of permanent staff in the van Bommel factory increased from 37 people in 1920 to 58 people in 1929. The company introduced new brands using English names following the trend that began after the invasion of American cheap brands that became very popular in the Netherlands. However, the English brand names were banned by the government shortly after in order to stimulate domestic production during the years of the Great Depression.

The growth and expansion of the Van Bommel business continued and the number of employees was estimated at 60 people in 1930. In addition to that, the company had a manager, a modeler, a head representative and a representative.

They were later replaced by the son of director Franciscus Johannes van Bommel, J.P.J. (Jan); he became first a manager and later took over the position of head representative.

The company started applying innovative marketing ideas such as participating in the travelling trade fair (the First Dutch Exhibition Train), which travelled across the country and gave Dutch entrepreneurs the opportunity to promote their company and products in the larger towns. Van Bommel’s expansion plans were disturbed by the German invasion to the Netherlands and the establishment of the rationing system in 1939, which forced van Bommel to cut production by half and then to stop completely in 1941. Van Bommel found an opportunity in this bad time and they started making rush ladies shoes.

Shortly after Van Bommel factory survived this four-year stagnation, a dramatic event took place in March 1951 when a fire brought down the family factory entirely. The Van Bommels, never loosing courage, did not stop the journey there and made the best out of the incident. They decided to build a new factory with the most up-to-date machines and equipment. The new factory was built in no time and the production resumed eight months after the big fire.

After the great success for the company in the sixties, the Public Limited Company was changed to a Private Limited Company and many changes were made to the company’s board of directors.

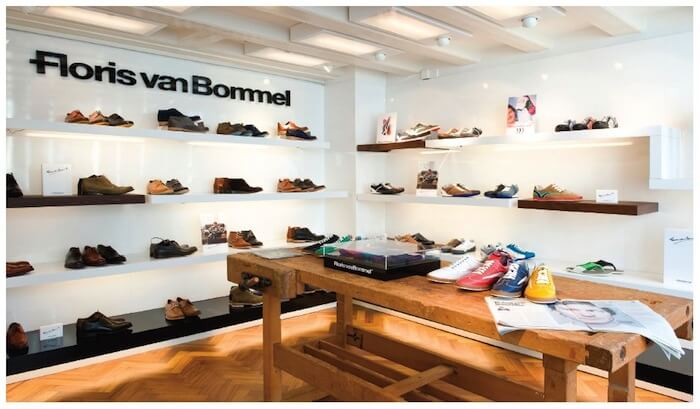

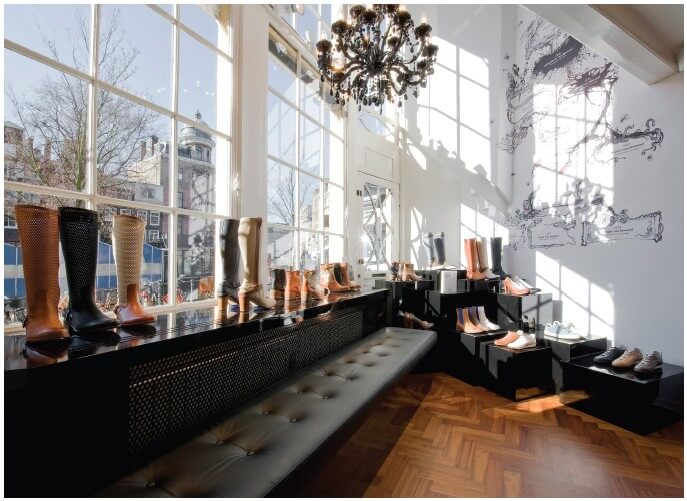

The Van Bommel Company with its entrepreneurial spirit solved the problem of the shortage in staff in the eighties by giving the opportunity to young people to learn the shoemaking trade in practice. In the 80s, the company had a strong presence in Europe with 60 retail outlets in Belgium and Germany. They also decided to move part of the ladies’ shoes production to Italy. The van Bommel brand kept growing and expanding in Europe with increase in the number of retail outlets in Germany to 70. Moreover, the company opened its permanent stand at the Trade Mart in Brussels, where all the shoe purchases are made by the Belgian retailers. Van Bommel was the first factory in the Benelux to receive the “Oscar Alta Moda 1982”. This Oscar is a high Italian distinction, awarded annually by the Chamber of Commerce of Turin, Italy. In 1993, the institute for Applied Shopping/Retail Research revealed that the van Bommel factory is the second most famous brand of shoes in the Netherlands. In 1996, the ‘Floris Van Bommel’ fashion brand was launched.

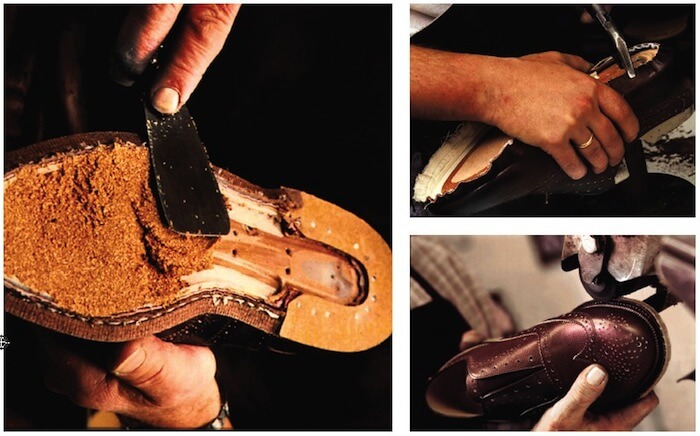

The business is run today by the three brothers of the 9th generation of the van Bommel family; Reynier van Bommel is theCEO, Floris van Bommel is the Creative Director and Pepijn van Bommel is the Commercial Director. With ambitious plans for the family business the siblings commit to the Van Bommels rich history of making ‘Superior shoes’. The Van Bommel shoes are made from Italian and French leather in the family factory in the Netherlands. The family also have production located in Tunisia, Serbia, India and Portugal.

Interview with Reynier van Bommel

The van Bommel family has always been loyal to its handcraftsmanship and high quality products. What is the secret behind keeping the highest standards in the shoemaking industry?

Making the right decisions at the right moment. In the past my forefathers have faced many crises and time after time they chose the path that was harder to take, the path of sticking to quality instead of benefiting from fast profits and high sales.

Mechanising some stages of shoemaking in the 20th century had both negative and positive effects on the industry. As a ninth generation family business member, would you change anything in shoemaking methods today?

In our factory in the Netherlands we have the highest standards regarding safety and health regulations. Even in countries in Europe a lot of the rules and regulations that have effect in the Netherlands don’t apply. I believe it would be good for our industry if we were all to apply the same rules regarding safety and health. Our workers are our greatest asset.

The presence of women in the company has been very strong over the years, Johanna van Dinter, the widow of Johannes Peter played a big role in mechanising the family factory with the help of her two sons. How much are the women of the family involved in the business today?

At present the ‘Van Bommel’ women are not involved. This is more a coincidence than that it was planned. My parents just had three sons, and no daughters. If they would have had three daughters instead I am sure we would have three ‘Van Bommel’ women in the business right now.

After establishing the Floris van Bommel brand for a younger demographic what was the response of your customers?

At first they started buying the shoes immediately. The new name and the somewhat younger shoes hit off very well with our customers. Some time later, after my brother and me came into the company and we started giving the brand its face and own signature we had some comments from our clients. They did not understand the way we were communicating the brand initially. Now they just trust us as a company to do well, they have seen that the ‘strange’ things we do actually work.

How long have you and your brothers been working together and how were the roles you hold in the family business allocated?

Floris and me have been working together for 12 years now. Pepijn started working in the company 1,5 years ago. At the moment Floris is the Creative Director, Pepijn is the Commercial Director, and I am the CEO.

Van Bommel has always fought its way through difficult times by adapting to change. Can you tell us more about the company’s adaptive strategy?

Always have quality as a first priority, not sales.

Does the van Bommel brand have plans for expansion to new markets?

At this moment we are occupied with the German market. We are doing very well there. In a few seasons from now we will be expanding to new markets.

Tharawat Magazine, Issue 11, 2011