The city of Dar Châabane, in Nabeul, Tunisia, is the home of traditional craftsmanship; it is best-known, however, for its experts in the art of stone carving. Sayadi Pioneer Stone Carving is a family business set up by a Dar Châabane resident, Mohammed Al-Saleh Bin Abdul-Salam Sayadi, nearly fifty years ago, originating from his passion for this craft and its rich history. In an interview with Tharawat Magazine, Eng. Lutfi Sayadi, son of Mohammed Sayadi, speaks about the various stages of development of the stone carving industry, the secret as to how his family has preserved the craft, and the challenges the family business is facing today.

The success and survival of the Sayadi Company is credited to a man who, besides being uniquely talented and skilled, has a passion and dedication that has made him, over time, an expert craftsman. He is the founder of the Sayadi Company: Mohammed Al-Saleh Bin Abdul-Salam Sayadi.Mohammed Sayadi grew up in the city of Dar Châabane in Nabeul, Tunisia, whose people are known for mastering the art of traditional stone carving. It was an evolving industry at the time and began to attract great attention. He joined the workshop of stone carving pioneer, the late Mohammed Al-Asghar Al-Qarawi (the guardian of the craft), who taught him for many years.

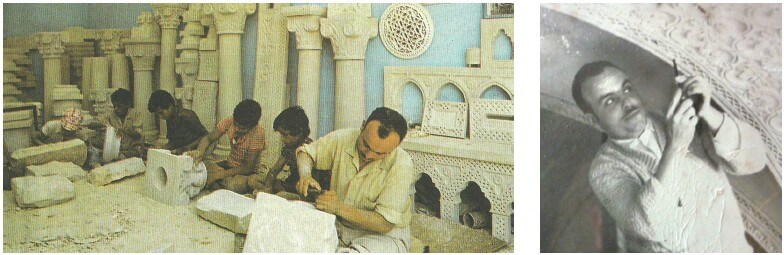

Mohammed quickly learned the secrets of the trade, starting from the extraction of stones from quarries in the mountains, through to cleaning stones and shaping them into various forms, and ending with decorating stones and turning them into works of art. In the 70ies, he worked alone, and sometimes with fellow craftsmen in the restoration, construction and decoration of many important buildings in Tunisia, including the decoration the main entrance of the presidential palace in Carthage. Mohammed also participated in the restoration of Al-Asram house, under the supervision of a UNESCO panel, and many other projects in Tunisia and abroad.

After Mohammed had won appreciation and encouragement from the culture and arts society in Tunisia, he decided to return to his hometown, and started in 1973 his own stone carving business, which would transform into a family firm over time. He continued his career in the design and manufacturing of high-quality pieces of work for the decoration and restoration of various buildings. Today, the family-run company owns several galleries in various Tunisian cities, as well as in the Gulf, Libya and Algeria. The number of its craftsmen increased from an initial nine to 50 trained artisans working in a new workshop.

The family-owned business has seen a marked development after the second generation, represented by Eng. Lutfi Sayadi, the founder’s son, joined the company in 1997. He started to organise the production processes and introduced modern technology and machinery to the business after he had developed the general strategy and vision.

The Sayadi family has preserved the fundamentals of the traditional craft, and continues to develop some of its aspects, undertaking the responsibility for maintaining this art and introducing it to an international audience.

Q&A with Lutfi Sayadi – 2nd generation, Executive Management, Sayadi Pioneer Stone Carving

When did you start working in the family-run company?

Officially in 2003, but I must say that I have been working in the craft since my childhood. I used to spend my school holidays learning our craft in a small workshop in the city of Dar Châabane. I learned the fundamentals, such as design, and methods of selection and classification of stones. I also learned how to engrave and carve on stones, but today I do not work as a craftsman. I work as a designer of production methods and models, in addition to being the official in charge of marketing and sales. I started to help my father practically after finishing secondary school in 1991. Before joining the family-run company and immediately after obtaining the certificate of industrial engineering I worked as the director of marketing in a pharmaceutical company. I chose that job in order to gain experience. I participated in establishing the firm. This enabled me to develop my experience, learn about foreign markets and understand the structure of projects and how to deal with the administration and management if companies. Since 2003, I have started to develop the method of production and diversification of our products and introduced a quality surveillance system.

How did the family-run business expand internationally since its creation?

Mohammed Saleh Sayadi was known locally and became famous for his dedication and the quality of his products. As the craft is traditional and based on labour without the adoption of modern methods, and because the workshop included only about 20 artisans, our company could not meet the size of international demand. At the end of the 80ies and due to the high demand, modern machines were introduced to make up for part of the manual work. These methods have enabled the company to expand its production. Thus, we started to look for overseas markets. We participated in some international exhibitions and started to accept external orders. The search for appropriate logistical solutions for shipping and delivery took a long time. The second problem that had to be resolved was how to make the products match the global market needs. We had to study the market in terms of their architectural formations and the conformity with building structures. This required a long and costly study that contributed to a delay in the development of the company at the international level. We started engraving on artificial stones, as it is sometimes difficult to find colours in natural stones matching the customer’s request. Hence, our philosophy has changed from being handcraft-based into a manufacturing-based industry. However, a unit for traditional hand-crafted products has remained; the most important unit and a symbol of beauty and creativity to our company. By using artificial stones we were able to respond to some special orders, however, it must be noted that natural products are the most requested for exportation. And so, the business has undergone a professional development that enabled it to enter foreign markets. This development will continue so that we can keep abreast of the trends and ahead of the competition.

How did the stone carving craft evolve over the years?

In the 60ies, the main problem were the tools for extracting the raw materials, as we used traditional means which were very slow. For transportation we used donkeys. To make cylindrical parts, everything was done by hand and small iron tools. Today, everything is mechanised, tractopels are used to extract and transport the rocks, special cutting machines with special diamond tools are used for carving and more.

However, for the time being, we have other problems:

We cannot find artisans to do the handmade parts which is essential to keep the work true to type.

There are no different types of natural stone: many carriers stopped their activities because of the new ecological rules.

The biggest problem for the future: There is no next generation learning the stone craft work. We believe that to educate a good handcraft artisan you have to start at an early age.

Al Sayadi family has been considered a pioneer in the business of stone carving for many decades, what is your strategy in keeping the craft alive?

In order to keep our company up to date and able to go ahead, we tried through the last decades to keep in touch with the latest techniques enabling us to ensure good quality. We tried to encourage our workers and to make them identify with the projects. Also, since we belong to a small family, we are trying to keep our children in touch with the craft. We try to introduce them to the workshop during their school vacations. We believe that in order to succeed in running the family business, they should learn the principal and basic rules of the craft. The only way to do this is to practice and by being in love with handcrafted work.

What are the ingredients that you believe make a family business sustainable?

In order to run a family company you should…

Try to introduce many members of the family to the business

Be professional and forget the family relations within the work environment.

Design an organigram illustrating all the relations between employees and fix the limits of responsibility of each person independently from the family structure.

Try to introduce children at a young age, to give them the opportunity to discover the job

Train children to take decisions in a way to prepare them for management.

Keep in touch with the latest technology, to be innovative, creative and to compare your company to the biggest competitor.

This is the way enabling the company to remain sustainable over many generations.

Tharawat Magazine, Issue 14, 2012