Interview with Daniel Hager, CEO of Hager Group

Being dedicated to our work while maintaining a healthy private life can be a difficult task. Not least because the choice is not always ours; our place of work determines greatly how realistic our preferred life choices are. For most businesses, supporting work-life integration for their employees has become a great priority. Satisfied and balanced employees are less prone to stress-related illnesses, have an increased sense of loyalty towards the company and perform better. A remarkable example of the success a balanced work environment can produce, is Hager Group, a third generation family business.

Hager Group is celebrating its 60th anniversary this year. In 1955, Hermann and his brother, Dr. Oswald Hager, founded the enterprise together with their father, Peter, in Ensheim, Germany. What started out as an electro-technical factory that provided products to Germany and France, turned into a global enterprise. With solutions available in over 95 countries and with over 11,400 employees, the family business offers electrical installation solutions and services to residential, commercial, and industrial buildings. Needless to say the now third generation family business has come a long way since its beginnings. At the forefront of automation and energy technology, Hager Group is still very much a family business. Daniel Hager, third generation member and CEO of Hager Group, spoke to Tharawat about acquisitions, the balance between work and life, and the propagation of a sustainable vision.

Why and how did you get started in the family business?

I officially joined in 2003. When you are part of a business legacy, I guess you always have an eye on the firm no matter what you do in life. After studying business, I decided to get some outside experience to see what I was capable of. When the time came, I had a discussion with my predecessor, who was not a family member and was planning for retirement. When I finally came aboard, I felt it was a great challenge but an even greater opportunity.

I had a lot of work experience within the company before reaching the top. The fact that my own family ran the business made it rather easy for me to assimilate the values and vision. Today, my brother and my cousin are on the supervisory board. My other cousin, Peter, is involved in managing relationships with electricians. Even my 88-year-old father still comes to the office every other day.

Hager employs thousands. How is a family firm able to manage such a large work force?

Our organisation is based on a dualistic model. From a business and a legal perspective, we are a European company (SE, Societas Europaea). The family elects a supervisory board which then designates the executive board. The executive board is in charge of the business. We have split the operative plan and long-term strategy, the latter is devised by the family.

[ms-protect-content id=”4069, 4129″]

Could you tell us about the recent acquisitions the firm has made?

Over the past 20 years, we made acquisitions at the rate of one company a year. In recent years, these acquisitions were much larger. For example, we acquired the Berker Firm in 2010, and Bocchiotti in 2015. All acquisitions happen along one of three axes: to extend our product portfolio, geographically expand, or acquire new technologies.

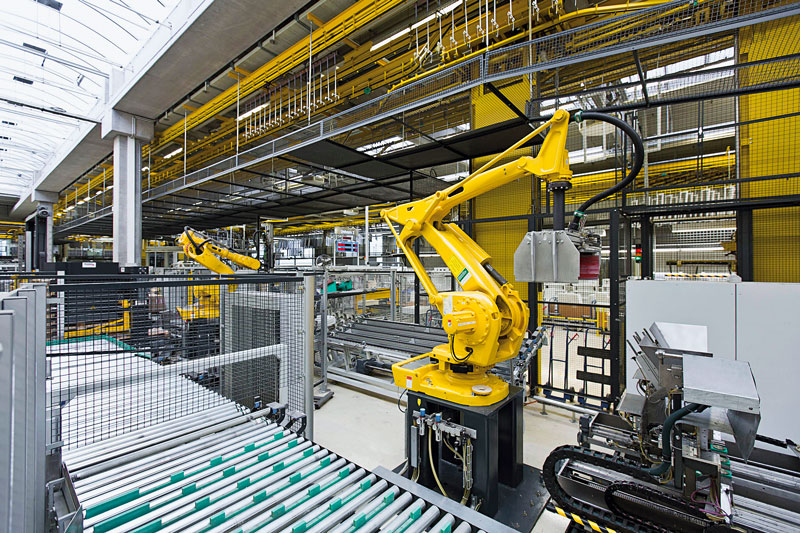

Picture: Hager Group plant in Blieskastel, Germany

In order to succeed post acquisition or merger, we adopt the attitude that we know nothing about the company. We may know the figures but we don’t know the culture. We go in, we learn, and then we establish a common plan to proceed. We have acquired other family businesses in the past. The process is usually smoother than for other types of companies. Family businesses share common values and principles of business. Even post merger, we often see that the cultural fit is best with other family firms.

Hager puts a great emphasis on sustainability. Can you tell us more about your E3 strategy and why it matters?

Every family business is, by definition, sustainable because as a family, we do not just look at quarterly or annual profits, we plan for the next generation.

How though, can sustainability be reinforced as a philosophy in a structure comprised of over 11,400 employees? To answer this question, we came up with the E3 model. The first E stands for “ethics” in all relationships, be they with internal or external stakeholders. The second E stands for commitment to the “environment”, a family priority from the very beginning, as my grandfather could not tolerate waste. The third E stands for “energy” and how it can be preserved through the efficient use of electricity.

We trained our 80 executives in the E3 model during a week-long Management Summer School. Although they already acted responsibly, the concept helped them uniformly transmit the message to our employees.

Today you offer support and training to all your employees. How has your approach to employee development changed over the years?

There are many opportunities for our employees, at all levels. My grandfather, father and uncle were adamant about providing training. If you want to keep the best on board, if you want to retain talent, then you have to provide them with the possibility for growth and improvement.

It is also important to emphasise that we still manufacture in Europe, whereas many of our competitors have outsourced their operations overseas. We achieved highly automated standards in our European factories because of our commitment to training. We taught craftsmen used to working with their hands how to supervise machines. Many felt the internal satisfaction of job growth. We trained and hence retained them. It was a win-win situation.

We also support the reverse process by giving more people the opportunity to learn about the craft. We established a tooling school in order to encourage people to learn the profession because we will soon lack this specific know-how as many of our employees in this field will retire over the coming years. Other companies around our tooling school are also interested in training their own employees in this school because they end up as certified craftsmen.

Do you consciously promote a work-life balance in your business? Is it something that you feel you have yourself achieved?

It’s a daily struggle for everyone, I think. I mean balance is never perfect, never a final state. Everything is always moving. Because of that, being balanced sometimes means doing more of something. It is about finding the middle state at every step of the way. This is critical to performing well in business and at home.

We offer Care Management to all our employees, emphasising the importance we place on living a balanced life between work and home. We have a dedicated department which tailors the services we offer for employees according to the country they reside in. We give them the options of a wide range of sports activities, childcare in the workplace, detailed safety trainings, and health care programmes that include vaccinations, just to name a few. Training opportunities, as I mentioned earlier, along with career development counselling are also available.

Since 1994, we have achieved and maintained the Investors in People accreditation. We are actually one of the first European firms to do so. The framework allows us to monitor employee development and career management throughout the organisation and includes external auditors coming in to make sure everything runs smoothly in that respect.

Diversity is also very important to us. We are now faced with the millennial workforce who put more emphasis on flexibility. We naturally have to adapt and have started systems that allow for remote work.

Do your products also add to consumers’ work-life balance?

We produce devices for home automation that make our customers’ lives more comfortable. Whether these things ultimately save time is debatable, though automation is undeniably up and coming. If you look at what the next generation has already achieved with iPhones alone, then you know that there is no stopping it.

When you make a home, you usually plan for the next 20 to even 40 years, whereas the lifespan of a device is usually much shorter. This contradiction must be integrated into the way we engage home automation. Right now there is debate about whether or not it is safe to integrate all this automated technology in our homes and vehicles. I think the safety issues will be resolved very soon. The next generation will also know how to better balance out their time with technology. It will come more naturally. This is validated when I watch my 8-year old son use an iPad with incredible ease.

Do you believe that being a family business at your size of operation is still a marked advantage?

I think it is about accountability. I would say that today each one of our employees is accountable for his or her area of work. Of course, it is good for them to know that they are not working on behalf of anonymous shareholders, but a very visible shareholding family that maintains its values.

Tharawat Magazine, Issue 27, 2015

[/ms-protect-content]