In order to return to the roots of the Busatti family’s origins in business we must travel over two centuries back in time. In 1796, between Tuscany and Umbria, the geographic centre of the Italian Renaissance and birthplace of legendary artists Michelangelo, Leonardo da Vinci, and Rafael, laid the Castle of Anghiari, a textile factory, which specialised in weaving cloth for the uniforms of Napoleon’s troops stationed in the region’s hilly plains. The Busatti family, having been in the region since 1790, took over the textile factory and ushered it through a succession of successful periods. Soon after the Busatti family’s procurement, the textile factory began to cater to the needs of its local customers and by 1808 was entirely consumer-focused. Around the middle of the 19th century the family, having stocked the finest materials, specalised in home linens, built hundreds of handlooms, and gradually became known for the most lauded craftsmanship of the industry. The company now has 41 stores in Italy, 23 abroad, and thousands of customer accounts, which bear Busatti products.

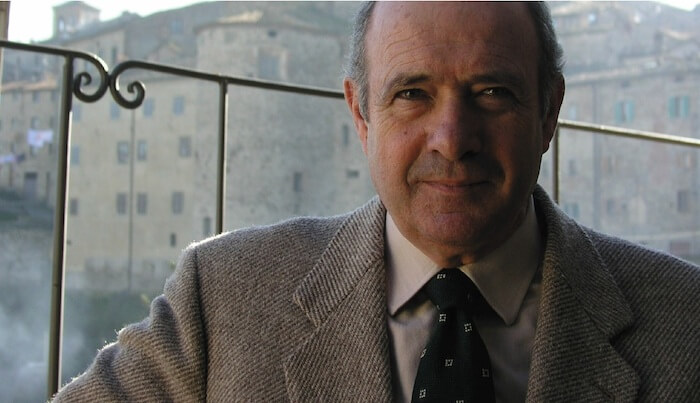

Interview with Giovanni Sassolini Busatti

In the following interview Tharawat magazine spoke to Giovanni Sassolini Busatti, a member of the eighth generation of the Busatti family and the current President of Busatti. In 1976, Mr. Busatti took over the management of the company alongside his sister Elena and the two have since positioned Busatti’s products in the market to a degree of worldwide acclaim.

[ms-protect-content id=”4069,4129″]

What were the major strategic milestones in the Busatti family business history?

The first strategic milestone was to decide to transform the demand for textiles for Napoleon’s troops into a steady supply to the local community. When the company started, we were supplying hospitals and the army. We had very simple products like hundreds of other companies in Italy and soon became established in our community.

The second strategic decision that had long-term consequences for us was when modern machinery was introduced and all our competitors modernised and went into mass production. At the time we could not afford to make the same improvements, and so kept producing with our traditional machinery. After a while, the electronic machines were available to everyone in the market. Over the last few decades, however, Asian markets, providing low labour costs became too competitive and put many of our competitors out of business. So it turns out that what initially was a disadvantage turned into our family’s greatest competitive advantage: By using the traditional methods, Busatti products are now categorised as luxury goods. No one else produces with old looms, and old techniques. We are still producing our goods in the same building, which is 500 years old. It’s a bit of industrial archaeology.

Naturally, we went through other critical stages with our business in our 170 years of history: The First World War, the Second World War, the economic crisis of 1929, along with some other minor local crises and disputes. Overcoming these was only possible by making key strategic decisions. Another defining step for us was to begin by expanding our reach in Italy, which at that time was our commitment. Our first six stores were in our immediate surroundings, and then we expanded into other cities and later into other countries.

Is there a structure in place to involve the next generation of Busatti family members?

No, not really. I think maintaining our business is a part of our DNA. Out of my three sons, two are involved in the company; they represent the ninth generation. We all are active in the many phases of our value chain. I believe that as an owner you have to know each stage of production. Dirtying your hands is necessary because then you understand what it means. Of course, lately, we have also included more modern technology and our other family members are involved on the board of directors.

What were your methods for internationalising the Busatti brand?

To take our products international we started to attend trade shows to promote the brand and to meet new customers. Today, we have 23 Busatti stores around the world and are present in other stores in dozens of countries. We also supply important high-end department stores in the US. We have found that our partnerships have only been successful if there was a commitment to educating the customers on our products. Today, we have our own collections of table, kitchen, bath, bed linen and produce accessories, such as bags and shoes as well. Our customised range presents about 40 if not 50 per cent of our production. You know, everyone dreams to have something which is unique; something that only they can own. And that’s what we like to provide our customers with. I often say that Busatti is for everyone, but not for anyone.

When internationalising as a family business you have make sure that you stay true to yourself. You have to believe in your products and never compromise. You might not make the big money at once, but if you invest yourself wisely you can create a legacy in the long run. It’s a choice: A lot today, and nothing tomorrow or understanding an investment and the delayed gratification it can bring to the business.

We have promoted Busatti internationally, not only by proposing a product, but also by explaining how it is made, the history, and the family values behind it. The future and the present are built on the past. Never disown tradition.

How are you maintaining the company’s competitive advantage in the luxury sector?

I think that a mixture of circumstances have led to our position today: My mother’s hardships as a widow with eight children and therefore not being able to modernise the machinery, the decisions of our competitors which eventually put them out of business, and of course our own family philosophy which has always emphasised quality above everything else. Today, I am often asked to lecture at universities about positioning in the luxury segment. People are wondering how we survived this long with our traditional methods still intact. Maintaining our competitive advantage has now become second nature to us as we do not really have any competition considering our highly customised and quality oriented approach. When customers ask us for large quantities of our products the answer is always ‘no’ because we simply don’t carry large stock to maintain our bespoke strategy.

Of course our competitive advantage is sometimes threatened by the current economic situation: People are now more price-oriented than ever. This is why we insist on educating our customers so that there is an understanding that sometimes paying a higher price for a quality product pays off in the long run.

Tharawat Magazine, Issue 18, 2013

[/ms-protect-content]