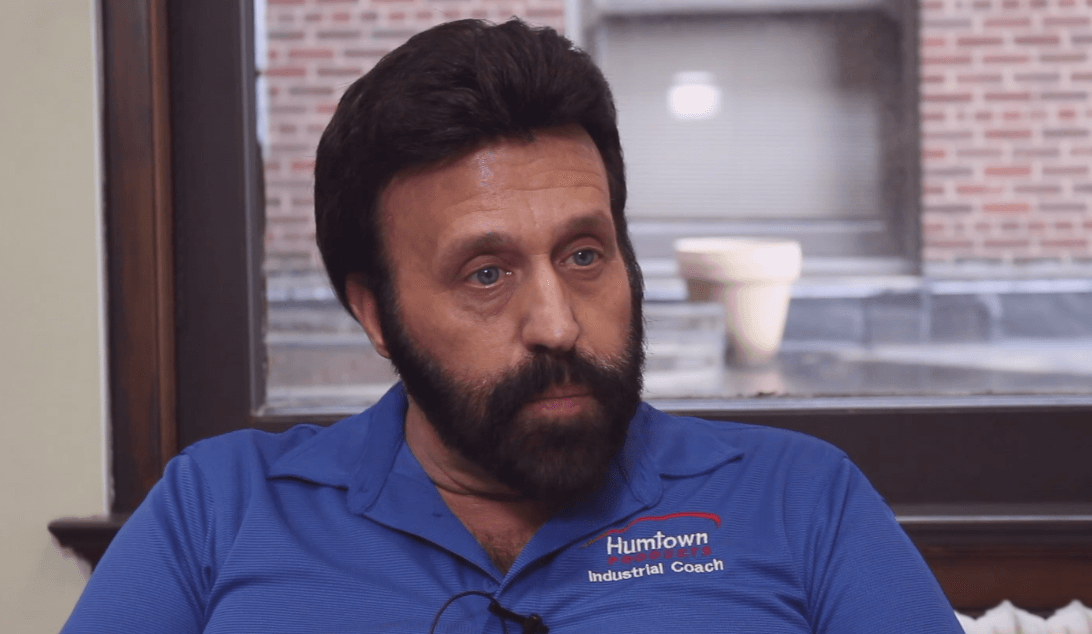

When the economic recession hit America’s industrial heartland, second-generation owner Mark Lamoncha used technology to empower his team members and save his family business.

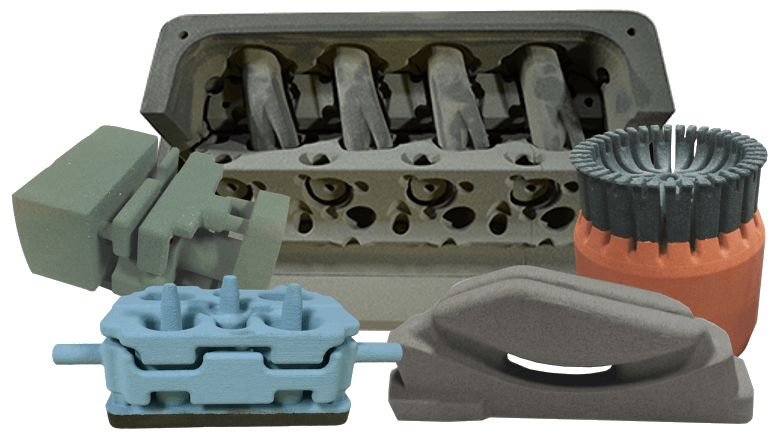

Humtown has been producing industrial cores and moulds in Ohio since 1959. Just as it did to many other manufacturing businesses in the Midwest and around the world, the 2008 economic collapse brought disaster. Humtown went from more than 200 employees to 17.

Unbowed, Lamoncha saw an opportunity to implement an idea he had long been considering.

He knew that unlocking the human potential of his team members was the key to redefining Humtown’s competitive advantage. So, to heighten their engagement, he incentivised performance by converting the labour portion of the job to a visual earning rate in real-time, engaging them in their task. For Humtown team members, a higher output translates to a higher earning rate, which is updated every cycle and displayed on a nearby screen. To add to this, Humtown uses gamification to foster a dynamic of positive competition.

Lamoncha recognises that a business and the sum of its team members are one and the same: when team members win, the business wins.

Prioritising people has led to a wider transformation in Humtown’s culture, of which the visual earnings system is only a part. For example, there are no supervisors on the factory floor. Instead, there are performance coaches whose express purpose is to help workers and, by extension the business, perform better. The results are staggering: Humtown’s productivity increased by 400 per cent on the first job the system was installed on.

Recently, Tharawat Magazine sat down with Mark Lamoncha to discuss the economic crisis as a catalyst for change, engaging team members in the digital age and how people-oriented managerial practices transformed his family business.

The story of Humtown’s revival begins where many others ended – the 2008 economic crisis. How did your business survive?

The recession taught me a powerful lesson: it’s not about what we make or how we make it but rather the why inside of the people. My search for a survival strategy brought me to Lincoln Electric, a company that implemented an annual performance-based compensation system for its employees in 1934. Their story resonated with me. I was also trying to find a way to move our people past pay rate towards a fair work-based earning system.

“Before implementing the system, we were producing 400 to 500 parts in an eight-hour shift. The new system saw productivity increase by 350 to 400 per cent.”

We applied the principles of Lincoln’s performance-based earning matrix to Humtown’s operations with a revolutionary digitised system – one that shows the earning rate of an individual team member as they cycle a machine. The results of their work, displayed nearby, are immediately apparent, like an unofficial industrial engineer sharing by-the-minute insight.

Before implementing the system, we were producing 400 to 500 parts in an eight-hour shift. The new system saw productivity increase by 350 to 400 per cent.

The system also shed new light on productivity from a managerial perspective. We saw that employees perform better in six-hour shifts, and we modified our scheduling to reflect this insight.

Suddenly, we were making 1,440 parts in a six-hour period, where before we made 400 to 500 in eight.

How did you build on that initial success?

I’m passionate about unleashing the most significant source of untapped energy potential on earth – human potential. This means empowering employees by giving them the necessary tools for self-management.

As such, our company operates a coaching model; we don’t supervise or manage. Employees combine skill and execution to become industrial athletes at their workstations. We apply the level of performance expected in sports to an industrial setting.

Competition, also in line with the sports analogy, is another integral part of our shop-floor dynamic. When people can track their progress in real-time, the drive to overtake others becomes a powerful motivating factor. Playing the game engages employees in their performance.

To take this even further, we incorporated video game elements as well. For example, fireworks go off on an employee’s screen when they reach $20 an hour. If they get up to $25 an hour, they see a picture of themselves, and if they hit $30 an hour, dancing flames come up in front of their picture. We make the workplace fun and engaging because engaged workers are focussed, purposeful and passionate.

Disengagement, according to a recent gallop poll, costs the American economy US$550 billion dollars a year, not to mention that only 3 out of 10 are engaged in their jobs. Their disengagement translates to higher rates of both accidents and defects.

Recently, an OSHA audit concluded that we are in the top 5 per cent in the state for positive safety culture as a result of these initiatives. As far as quality goes, when the aforementioned job making 1440 parts per shift was under a pay rate, the scrap rate was 8 per cent. After installing the visual earnings system, the scrap rate dropped to below 3 per cent.

Has Humtown’s culture changed as a result of these initiatives?

Absolutely. We implemented a reverse-engineering project on team staffing at the same time. Now, when we recruit, recruiters complete an assessment rather than giving candidates a test. The system matches the critical thinking, interest and behaviours required for the position to the person. Previously, we had a 70 per cent turnover rate. Now, that figure is as low as 5 per cent.

The advent of the six-hour workday has also had a significant impact. Some of our people come in at six in the morning and leave at noon so they can go to college. Promoting unity and emphasising the work-family aspect has always been a priority at Humtown. For example, on Fridays, we bring in outside vendors like BJ’s and Olive Garden and have a family meal together, which is followed by a topical discussion on self-development, safety and teamwork. These latest initiatives have only heightened the feeling.

The results of this culture change speak for themselves. Some of our people make as much as $100 an hour on a project, which means one person is doing the work of ten. Essentially, they pulled our schedule ahead by nine hours in that one hour. This means they saved us $1,800 while rewarding themselves at the same time.

Are there plans to export this system to other businesses?

We patented it 14 months ago, and currently, we’re in the middle of a seven-week gBETA national incubator with the intent to take it public. Our system requires that we do a full payroll every cycle of the machine. To scale with speeds like that and to bring our six-hour-long video game experiences to life, we need partners like Oracle and Pixar.

“…We need managers and policymakers to see that shorter shifts create focus and stimulate productivity.”

What other industries might benefit from adopting Humtown’s approach to workplace performance?

The system is widely applicable. Software algorithms like the one we use can be written for service work across industries, calculating labour cost against manufacturing unit into a visual earning rate that is then coupled with gamification.

The medical sector stands to benefit hugely from a shorter workday. We have seen a dramatic reduction in fatigue and quality errors since moving away from the conventional eight-hour shift.

Mandating a six-hour workday in medical professions would also create hundreds of thousands of new jobs. First, though, we need managers and policymakers to see that shorter shifts create focus and stimulate productivity.

[ms-protect-content id=”4069,4129″]

What needs to happen for these managerial practices to become widespread?

There needs to be a fundamental shift in mindset. The key is empowering people with technology, not using it to keep tabs on them.

Recently, while giving a presentation on Humtown’s real-time earning system, I met an award-winning businessperson that exemplifies this attitude. He explained how he used track reading technology to read the power on his machines, so he could surreptitiously watch his employees and see when they were not working.

Despite production going up by 25 per cent as a result, his initiative is still a failure in my eyes; this is exploiting people rather than empowering them.

“We need to have equipment that complements people, especially where repetitive manual labour can cause damage.”

Has automation helped or hurt the people in your industry?

It all depends on how it’s utilised. We must remember: the human holding the cell phone is always greater than the device itself.

We need to have equipment that complements people, especially where repetitive manual labour can cause damage. Automation and technology have the incredible potential to enhance human performance in the workplace and mitigate the possibility of injury.

How will family businesses survive the next recession?

Regardless of their industry, businesses are sustainable only as long as they embrace next-space technology. If you are not in the next space, you are out of space – look no further than Kodak and Blockbuster.

I saw a space for Humtown in 3D sand printing manufacturing. So, we started a collaboration with YSU and became one of the largest commercial-use 3D sand printing companies in the world.

It’s my responsibility as the leader of a family-owned company to identify that next space, so our people still have a place to work. However, it’s this philosophy and the people it prioritises, not the technology, that will see us through.

[/ms-protect-content]